Strapping Band Thickness Guide Balancing Strength and Cost

- Views:0

- Author:Packaging

- Publish Time:2025-08-12

- Origin:site

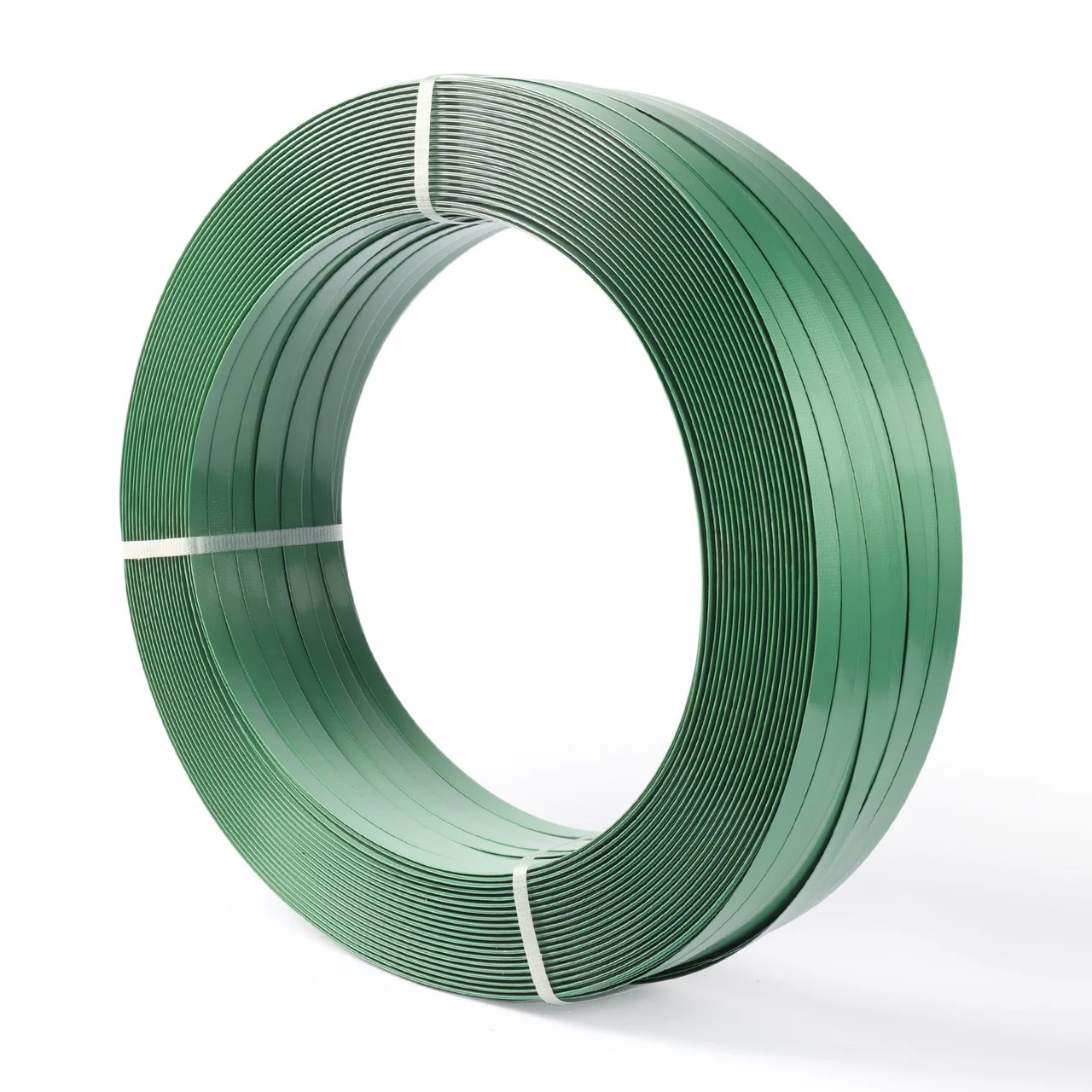

When it comes to securing and bundling products, choosing the right strapping band is crucial. The thickness of the strapping band can significantly impact both its strength and cost-effectiveness. In this guide, we’ll explore how to balance these two factors to ensure you make the best choice for your needs.

Understanding Strapping Band Thickness

1. The Importance of Thickness

The thickness of a strapping band affects its tensile strength and ability to withstand stress. Thicker bands typically offer greater strength, making them ideal for heavy loads. However, they also come with a higher cost. Understanding the right thickness for your application is key to optimizing performance and budget.

2. Common Thickness Options

Lightweight Bands (0.5mm - 1.0mm)

Best For: Light-duty applications, such as bundling small items or packaging lightweight products.

Advantages: Cost-effective and easy to handle.

Medium Bands (1.0mm - 1.5mm)

Best For: General-purpose use, suitable for moderate loads and a variety of packaging needs.

Advantages: Offers a good balance between strength and cost.

Heavy-Duty Bands (1.5mm - 3.0mm)

Best For: Heavy loads and industrial applications, ideal for securing large packages or pallets.

Advantages: Provides maximum strength and durability, ensuring safety during transport.

Balancing Strength and Cost

1. Assess Your Needs

Before selecting a strapping band, evaluate the specific requirements of your project. Consider the weight of the items being strapped, the conditions they will face during transport, and your budget constraints.

2. Cost-Effectiveness

While thicker bands provide enhanced strength, they also increase overall costs. Analyzing your budget allows you to determine the optimal thickness that meets your strength requirements without overspending.

3. Testing and Feedback

Conducting tests with different thicknesses can help you find the perfect fit for your needs. Gather feedback from your team on ease of use, handling, and performance to make informed decisions.

4. Consult Experts

If you’re unsure about the best choice for your application, don’t hesitate to consult with strapping band suppliers or industry experts. They can provide valuable insights and recommendations based on your specific requirements.

Conclusion

Choosing the right strapping band thickness is essential for balancing strength and cost. By understanding your needs and evaluating the options available, you can make an informed decision that enhances your packaging efficiency.

Elevate Your Packaging Solutions with Our High-Quality Strapping Bands! Our extensive range of strapping bands in various thicknesses ensures you find the perfect match for your needs. Contact us today to learn more about how our products can optimize your packaging process!