PET vs. PP Strapping Bands: Which One Offers Better Cost Savings?

- Views:0

- Author:Packaging

- Publish Time:2025-10-30

- Origin:site

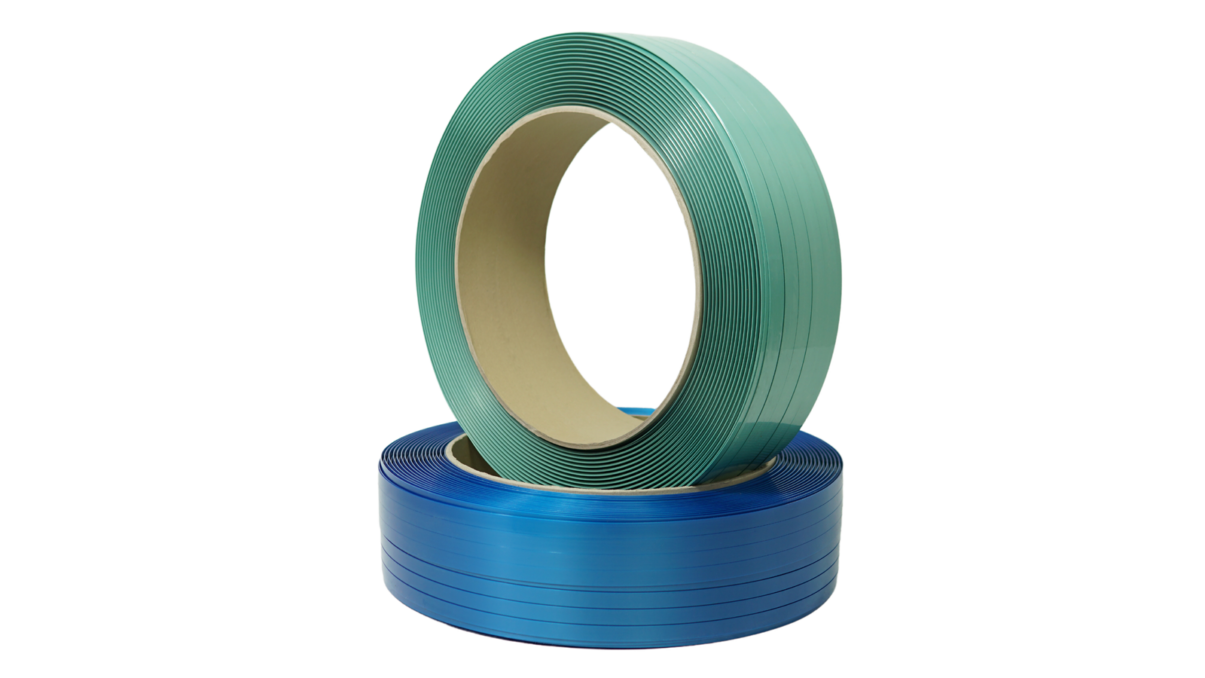

In the packaging industry, choosing the right strapping material is crucial not only for securing products but also for managing costs effectively. Two popular options, PET (Polyethylene Terephthalate) and PP (Polypropylene) strapping bands, each have their unique advantages and applications. But when it comes to cost savings, which one truly stands out? Let’s break down the features, benefits, and economic considerations of PET and PP strapping bands to help you make an informed decision.

Understanding PET and PP Strapping Bands

1. What is PET Strapping?

Durable and Strong: PET strapping is known for its high tensile strength and durability, making it an excellent choice for heavy and bulk packaging. It can withstand significant stress and strain without breaking.

Resistance to Environmental Factors: PET bands are resistant to moisture and UV rays, which means they can maintain their integrity even in challenging environments.

2. What is PP Strapping?

Lightweight and Flexible: PP strapping is lighter and more flexible than PET, making it easy to handle. It is often used for lighter packages and applications where flexibility is key.

Cost-Effective: Generally, PP strapping is less expensive than PET, making it an attractive option for businesses looking to minimize costs.

Cost Comparison: PET vs. PP

1. Initial Investment

Upfront Costs: While PP strapping is typically cheaper upfront, PET strapping offers enhanced performance that may justify its higher initial cost for specific applications.

Long-Term Value: Investing in PET strapping can lead to long-term savings by reducing the likelihood of breakage and damage during transit, ultimately protecting your products and reducing replacement costs.

2. Performance and Efficiency

Strength vs. Cost: If your operations involve heavy or fragile products, the strength of PET strapping can minimize losses, thus offering better cost savings in the long run. On the other hand, for lighter packages, PP strapping can be sufficient and more economical.

Operational Impact: The ease of use and handling of PP strapping may lead to faster packing times, which can also contribute to cost savings in labor.

Choosing the Right Strapping for Your Needs

1. Assess Your Packaging Requirements

Nature of Products: Consider the weight, fragility, and storage conditions of your products. For heavy-duty applications, PET may be the better choice, while PP could be ideal for lighter goods.

Budget Considerations: Analyze your budget and how much you are willing to invest in strapping materials. Factor in potential savings from reduced damage and enhanced efficiency.

2. Consult with Experts

Seek Professional Advice: If you're unsure which strapping type is best for your business, consult with packaging specialists who can provide tailored recommendations based on your specific needs and goals.

When it comes to choosing between PET and PP strapping bands, the decision ultimately depends on your specific packaging needs and budget considerations. While PP may offer lower initial costs, PET provides durability and strength that can lead to greater long-term savings.

Visit [https://www.strappackage.com/] or contact us at winnie@adtooo.com for more information on our range of PET and PP strapping bands. Let us help you find the perfect solution for your packaging needs!