How to Choose Strapping Seals for High-Vibration Environments

- Views:0

- Author:Packaging

- Publish Time:2025-10-15

- Origin:site

In industries where packaging is subjected to high vibrations—such as transportation, manufacturing, and heavy equipment—choosing the right strapping seals is crucial for ensuring the integrity and security of your shipments. The right seals can withstand vibrations and maintain a tight hold, preventing damage and ensuring that your products arrive safely. Let’s explore how to select the best strapping seals for high-vibration environments.

Understanding the Importance of Strapping Seals

1. The Role of Strapping Seals

Secure Packaging: Strapping seals are essential components that keep packages tightly bound, ensuring that the contents remain intact during transit.

Vibration Resistance: In high-vibration environments, inadequate seals can lead to loosening and shifting of the straps, compromising the safety of the shipment.

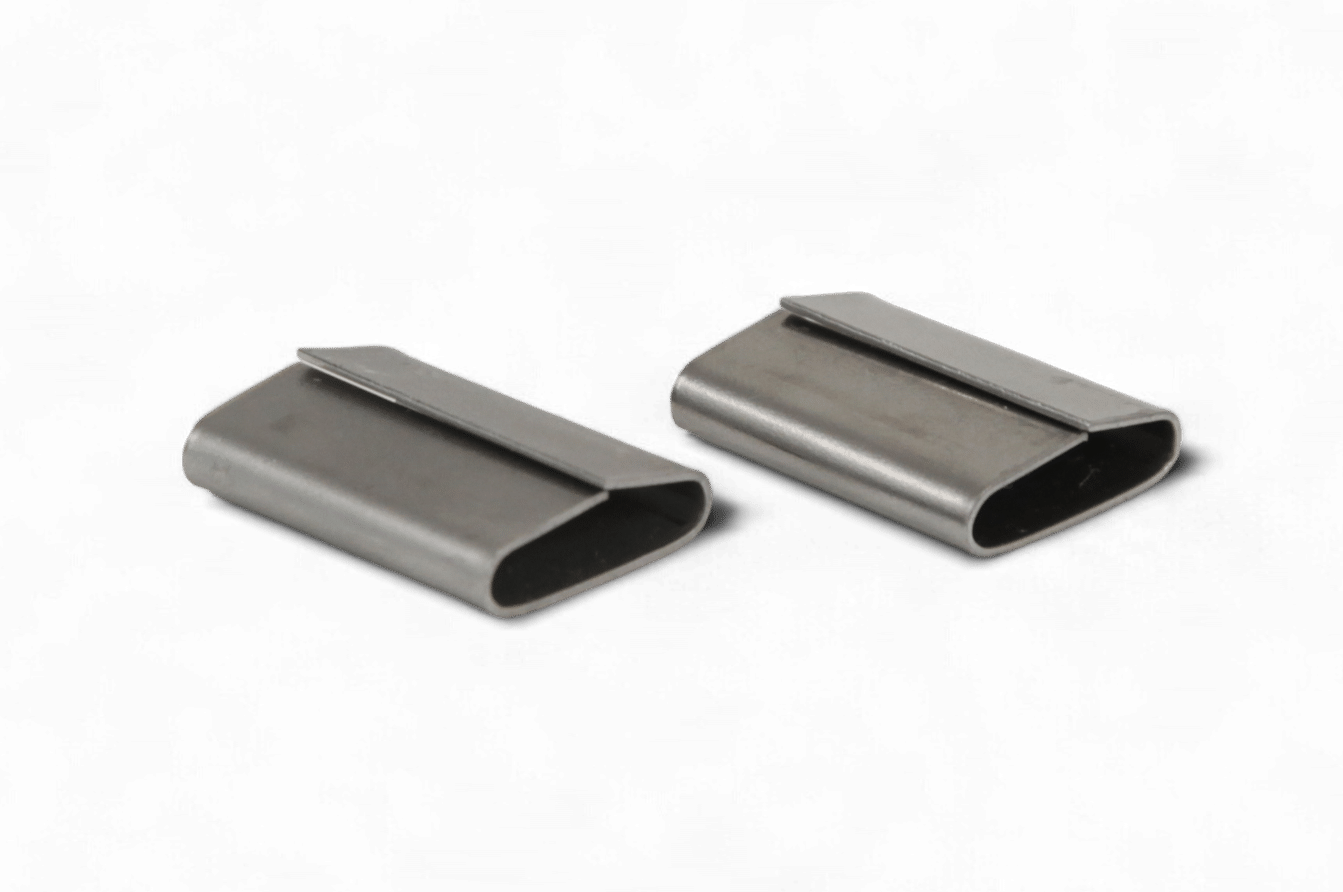

2. Types of Strapping Seals

Metal Seals: Known for their strength and durability, metal seals provide excellent resistance to vibration and are ideal for heavy-duty applications.

Plastic Seals: Lightweight and corrosion-resistant, plastic seals are suitable for lighter applications but may not offer the same level of vibration resistance as metal options.

Key Factors to Consider When Choosing Strapping Seals

1. Material Strength and Durability

Evaluate Load Requirements: Assess the weight and nature of the items being packaged. For heavy or bulky items, opt for metal seals that offer superior strength.

Environmental Resistance: Consider the environmental conditions, such as moisture or temperature fluctuations, which may affect the seal's performance.

2. Vibration Resistance Features

Design Considerations: Look for seals designed specifically for high-vibration applications. Features like ribbed surfaces or locking mechanisms can enhance grip and prevent slippage.

Testing Standards: Choose seals that meet industry testing standards for vibration resistance, ensuring reliability under challenging conditions.

3. Compatibility with Strapping Material

Strap Type: Ensure that the seals are compatible with the type of strapping material you are using, whether it’s polypropylene, polyester, or steel.

Seal Method: Consider how the seals will be applied. Some seals require specific tools or techniques for secure application, so make sure you have the right equipment.

Benefits of Using the Right Strapping Seals

1. Enhanced Security

Reduced Risk of Damage: By selecting seals that can withstand vibrations, you minimize the risk of package damage or loss during transport.

Improved Customer Satisfaction: Reliable packaging leads to fewer returns and complaints, enhancing your reputation with customers.

2. Cost-Effectiveness

Long-Term Investment: Investing in the right strapping seals can save you money in the long run by reducing product losses and improving efficiency in your shipping operations.

Choosing the right strapping seals for high-vibration environments is essential for maintaining the integrity of your packaged goods. By considering material strength, vibration resistance features, and compatibility with your strapping, you can ensure that your shipments arrive safely and securely.

Ready to enhance your packaging solutions? Contact us to learn more about our selection of strapping seals designed for high-vibration environments and secure your shipments with confidence!