Comparing Elongation Rates: PET, PP, and Steel Strapping Bands

- Views:0

- Author:Packaging

- Publish Time:2025-09-19

- Origin:site

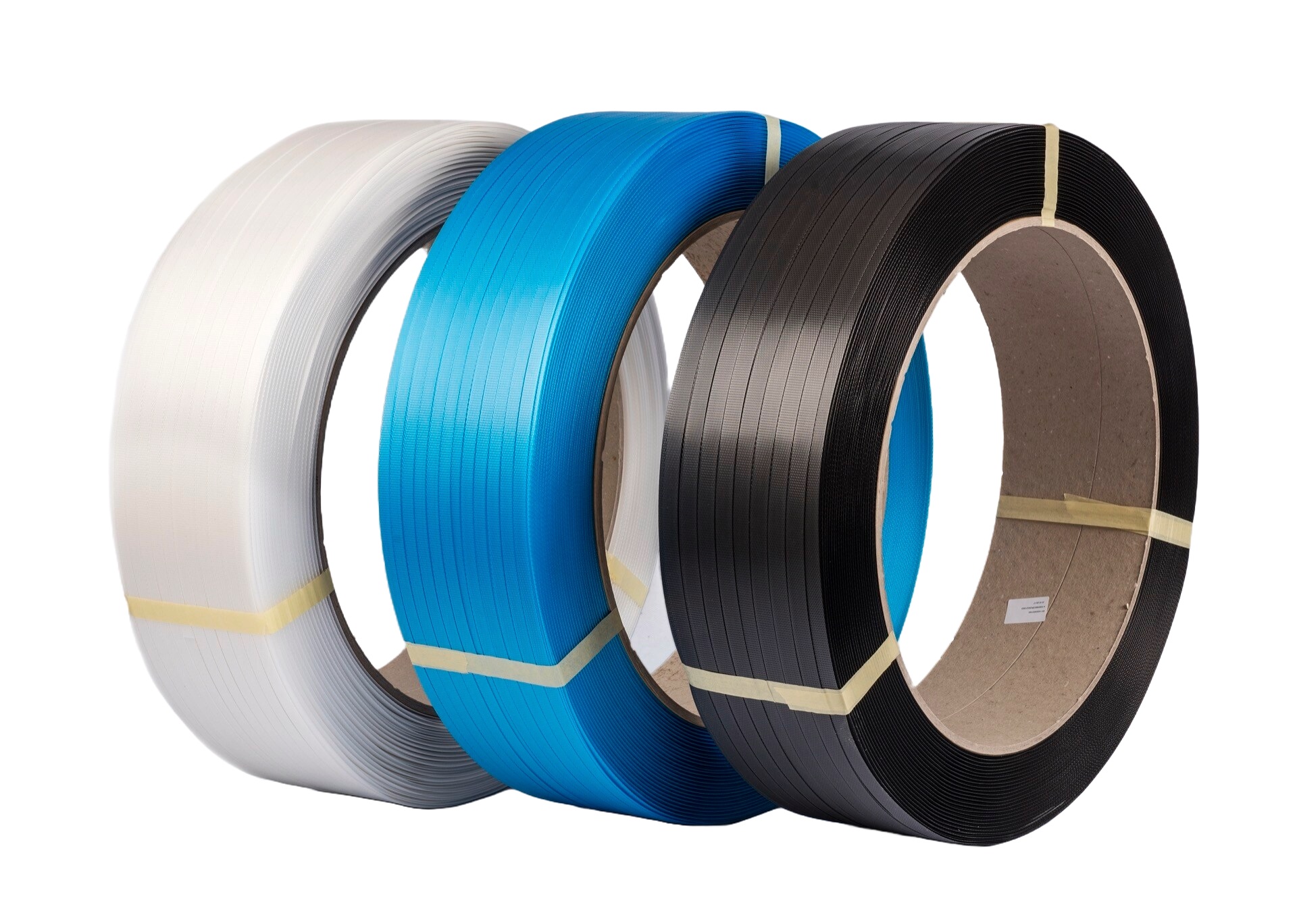

When it comes to securing packages for shipping and storage, choosing the right strapping band is crucial. The performance of strapping bands can vary significantly based on material properties, particularly elongation rates. Understanding the differences between PET (Polyethylene Terephthalate), PP (Polypropylene), and steel strapping bands is essential for selecting the best option for your needs. Let’s explore these materials and their elongation rates to help you make an informed decision.

Understanding Strapping Band Materials

1. PET Strapping Bands

Material Characteristics: PET strapping bands are known for their high strength and elasticity.

Elongation Rate: PET bands typically have a moderate elongation rate, providing a good balance between flexibility and strength. This makes them ideal for applications where slight movement is expected during transport.

2. PP Strapping Bands

Material Characteristics: PP strapping bands are lightweight and cost-effective, making them a popular choice for many packaging applications.

Elongation Rate: PP bands have a higher elongation rate compared to PET, allowing for more stretch. This can be beneficial for securing lighter loads but may not provide the same level of strength under heavy stress.

3. Steel Strapping Bands

Material Characteristics: Steel bands offer the highest strength and are often used for heavy-duty applications.

Elongation Rate: Steel strapping has a very low elongation rate, which means it does not stretch much under tension. This is ideal for securing heavy loads that require rigidity and minimal movement.

Choosing the Right Strapping Band for Your Application

1. Load Type and Weight

Lightweight Loads: For lighter packages, PP strapping may be sufficient due to its elasticity and cost-effectiveness.

Moderate Loads: PET strapping is a versatile choice, offering a balance of strength and flexibility for a variety of applications.

Heavy Loads: Steel strapping is the go-to option for securing heavy or bulky items that need to remain immobile during transport.

2. Environmental Considerations

Corrosion Resistance: If your products are exposed to harsh environments, PET or PP bands may be preferable due to their resistance to corrosion, unlike steel.

Temperature Fluctuations: Consider how temperature changes may affect your strapping choice. PET bands perform well in a range of temperatures, while steel can be susceptible to rust.

3. Cost and Budget

Budget-Friendly Options: If cost is a primary concern, PP strapping bands are often the most economical choice.

Long-Term Investment: For heavy-duty applications requiring maximum security, investing in steel strapping may save you money in the long run by reducing damage and loss.

Make Informed Choices for Optimal Performance

Choosing the right strapping band is critical for ensuring the safety and integrity of your products during transport. Understanding the elongation rates and characteristics of PET, PP, and steel bands will help you select the material that best suits your needs.

Ready to enhance your packaging solutions? Contact us today to learn more about our high-quality strapping bands and find the perfect fit for your applications!